Traditional Pipe Repair and Pipe Replacement

Years ago, plumbers would spend hours to days tearing up the ground around your home to reach and repair the damaged sewer pipe. This required you to shut off your home’s water supply, potentially leaving you with no running water for two to three days. While the plumbers ran loud equipment, exhaust fumes would fill the air, and your yard, driveway, and sidewalk would be torn up. Once the damaged sewer line was repaired, the yard around your home would need to be completely re-landscaped, costing hundreds to thousands of dollars.

Many homeowners used to put off their home’s annual drain inspection for fear that the plumber would find a damaged sewer line!

Modern, Trenchless Pipe Lining and Pipe Relining

Thankfully, trenchless technology means there are faster, less intrusive and more cost-effective pipe repair methods available today including cured-in-place pipes (CIPPs), and pipe relining. And that means you don’t have to worry about what your plumber might find during a drain inspection. In fact, scheduling drain maintenance every 12-18 months can actually save you money.

NEW! LIGHTRAY UV REPAIR METHOD

LightRay UV Repair is a game-changer for underground sewer pipe repairs. This state-of-the-art, trenchless pipe relining solution uses ultraviolet lights. The plumber lowers a bladder through a single, above-ground access point (typically a clean-out or toilet drain) or through the vertical stack access point on your roof.

Once in place, the plumber inflates the bladder with air pressure. Then, the UV lights are switched on, activating the resin’s curing process. With no disruption to your home or property, the existing pipe is completely rehabilitated once the epoxy resin is dry.

Non-Invasive Pipe Lining Solutions Backed by 40+ Years of Expertise

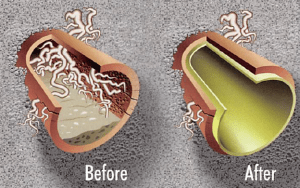

Pipe lining uses special epoxy to create a pipe within an existing sewer pipe, providing the same structural strength as a new pipe. This trenchless technology avoids the damage to structures, floors, interior walls, sidewalks, streets and landscaping that many traditional pipe repair methods cause. There are two primary types of applications, the ‘pull-in-place’ (PIP) method and the ‘inversion’ method.

PULL-IN-PLACE (P.I.P.) METHOD

The ‘pull-in-place’ (PIP) method pulls the epoxy-saturated liner into position and cures it into place. To pull a liner in place, two access points are required; one that feeds the liner in and the other that pulls it into place. In some cases, there is only one available access point. In these instances, the inversion method must be used.

The ‘inversion’ pipe lining method offers several advantages:

- Only one access point is required

- Up to 200ft of liner can be installed in a matter of seconds

- Epoxy is laid against the pipe, adhering the liner to the pipe

Did You Know: Most large pipe relining projects require a combination of the pull-in-place and inversion methods. There are several benefits to pipe relining technology. It effectively:

- prevents root intrusion and stops leaks

- increases flow

- prevents destruction of property

- has the same structural strength as new sewer pipes

What Are You Waiting for? Book a Sewer Line Inspection Today!

Maplewood Plumbing and Sewer has been repairing sewer pipes in St. Louis homes and businesses for more than 40 years. Our family-owned plumbing company prides itself on our solid reputation in the community. Give us a call to schedule your camera inspection and see for yourself why our loyal customers won’t use anyone else!

We offer a one-year warranty on all parts and labor excluding washers.

We are also experts in kitchen plumbing, basement plumbing, bathroom plumbing, and tankless water heater installation.

Give us a call at 314-645-6350 or fill out the contact form here to request a bid.